Florida International University Leaps into the Future with PNX Labs' Virtual Labs for Mechanics of Solids and Fluid Mechanics

Heat Exchangers, Francis Turbine, Tensile Tests and more!

In a bold move to revolutionize engineering education, Florida International University (FIU) has announced its decision to invest heavily in the development of virtual labs for mechanics of solids and fluid mechanics. Partnering with PNX Labs, a leading provider of virtual laboratory solutions, FIU aims to create an immersive, innovative, and interactive learning experience for its students. With the implementation set to commence in the Fall of 2023, this collaboration will see the development of virtual labs that encompass a wide range of experiments, including heat exchangers, flow measurement devices, centrifugal pump performance, and many more. This article explores the rationale behind FIU's groundbreaking decision and delves into the potential benefits and impact on students' learning experiences.

The Big Decision

Traditional laboratory education in mechanics of solids and fluid mechanics has faced numerous challenges, such as limited accessibility, high costs, and safety concerns. Recognizing these issues, FIU's decision to invest in virtual labs reflects the university's commitment to fostering a more effective and efficient learning environment. By partnering with PNX Labs, FIU aims to provide its students with a cutting-edge educational experience, equipping them with the skills and knowledge necessary for success in their future careers.

The Virtual Labs

PNX Labs will develop a comprehensive suite of virtual labs for mechanics of solids and fluid mechanics, covering a wide array of experiments. These virtual labs will include:

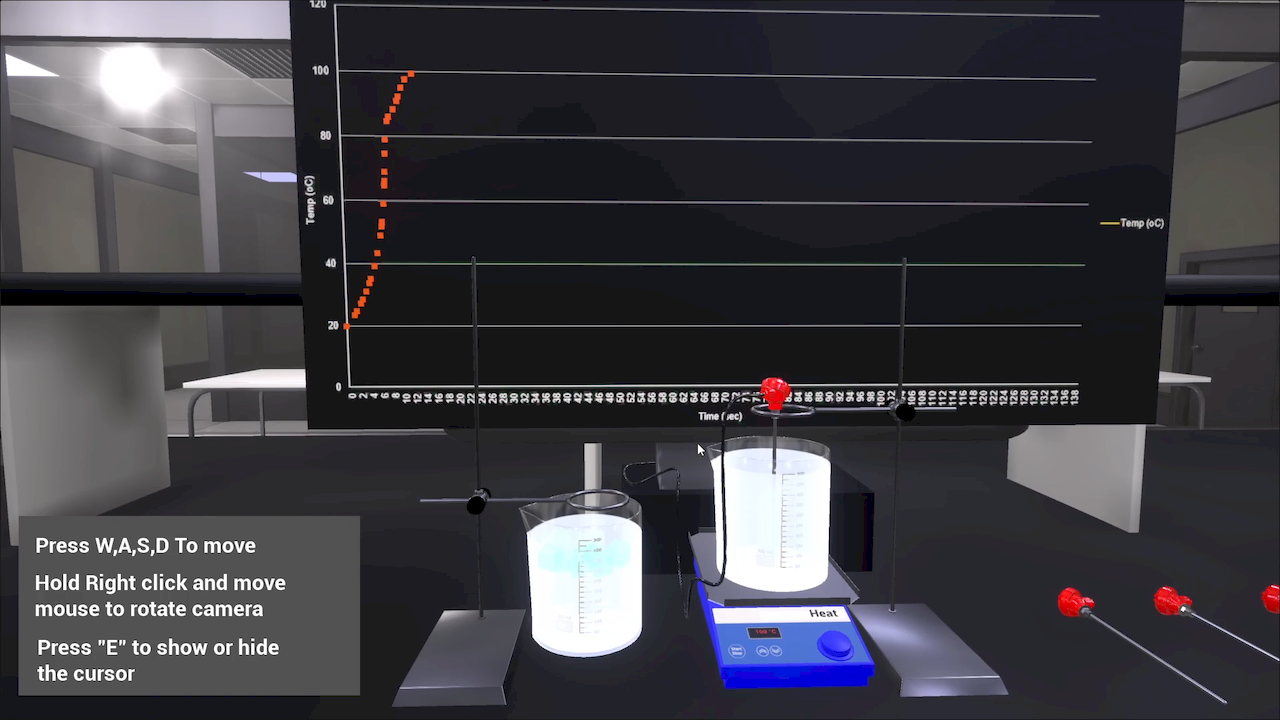

1. Heat Exchanger:Students will learn the principles of heat exchange and the operation of various types of heat exchangers, gaining valuable insight into their applications in engineering processes.

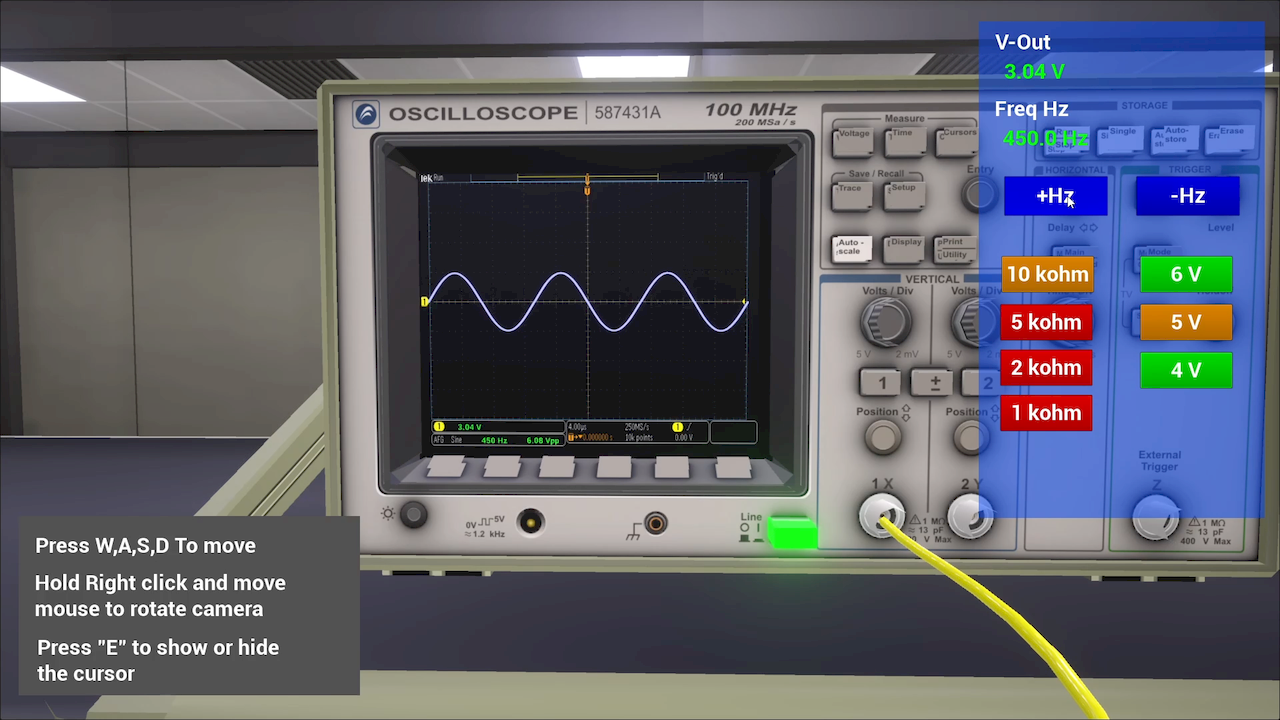

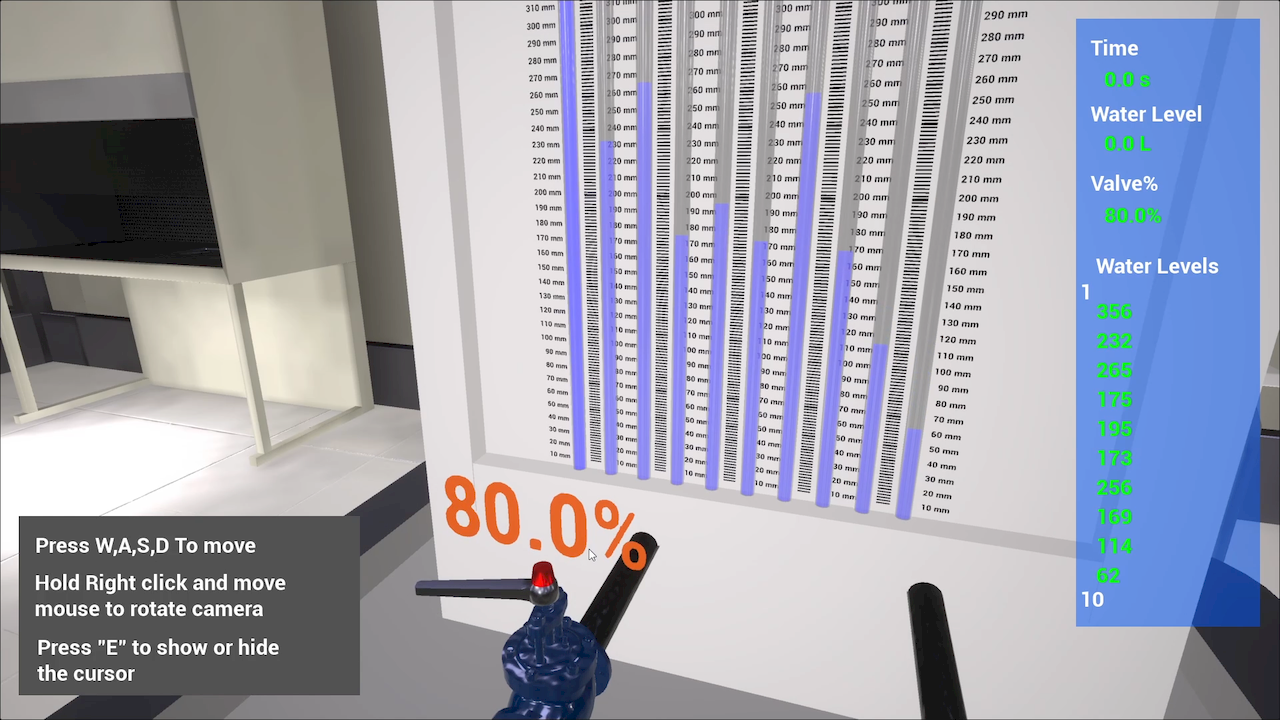

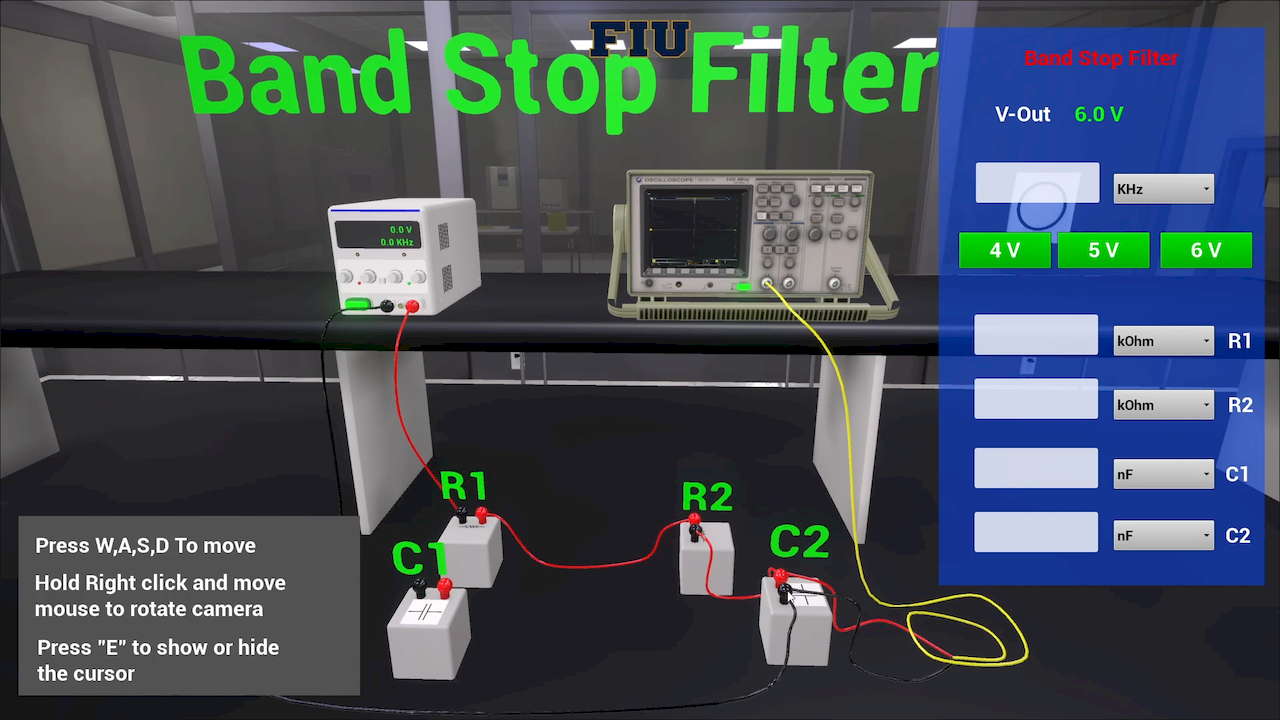

2. Flow Measurement Device: The virtual lab will cover different flow measurement devices, enabling students to understand their working principles, advantages, and limitations, as well as their significance in fluid mechanics.

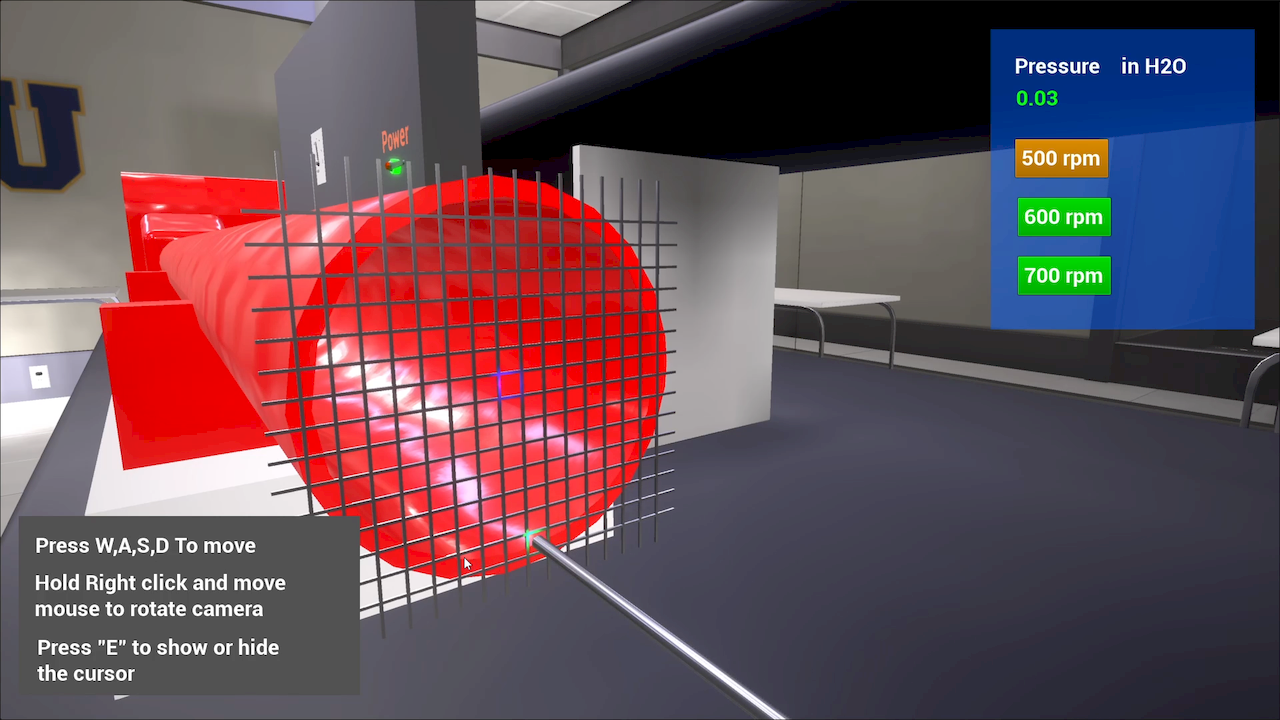

3. Centrifugal Pump Performance: Students will explore the factors that affect centrifugal pump performance, such as pump speed, impeller design, and system characteristics, and learn how to analyze and optimize pump performance in engineering applications.

4. Francis Turbine:The virtual lab will introduce students to the design, operation, and performance characteristics of Francis turbines, a widely used type of hydraulic turbine in power generation and water management systems.

5. Drag Forces and Streamlined Bodies:This virtual lab will enable students to investigate the effects of fluid flow on various streamlined bodies, learning about drag forces, flow separation, and the factors that influence drag reduction.

6. Lift and Drag Forces on a Symmetrical Aerofoil:Students will examine the lift and drag forces on symmetrical aerofoils, gaining an understanding of the factors that influence their performance and applications in aerospace engineering.

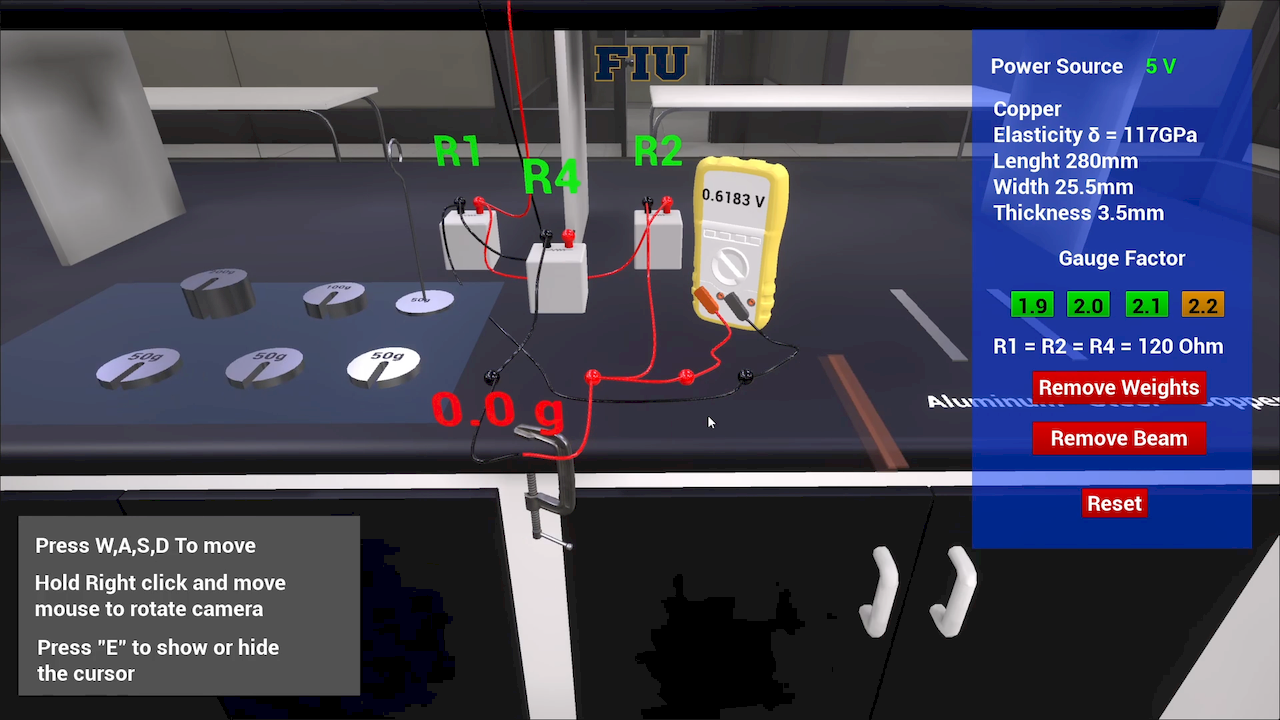

7. Beam Bending: In this virtual lab, students will analyze the behavior of beams subjected to bending loads, learning about stress distribution, deflection, and factors that affect beam performance in engineering structures.

8. Shear Force and Bending Moment: Students will explore the concepts of shear force and bending moment in beams, developing an understanding of their significance in structural analysis and design.

9. Torsion Testing: This virtual lab will allow students to investigate the torsional behavior of various materials, learning about factors that influence torsional strength and the applications of torsion testing in engineering design.

10. Euler Buckling:Students will learn about the Euler buckling phenomenon, exploring the factors that influence the critical buckling load and the importance of considering buckling in structural design.

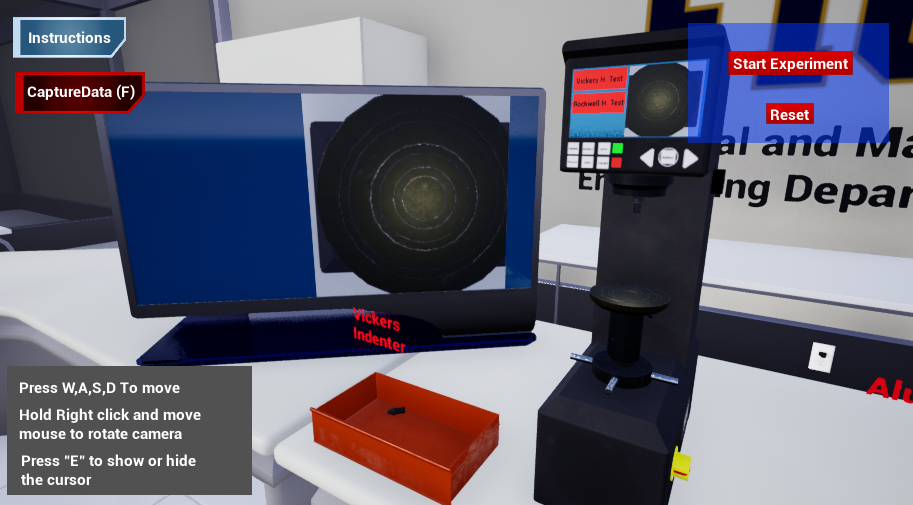

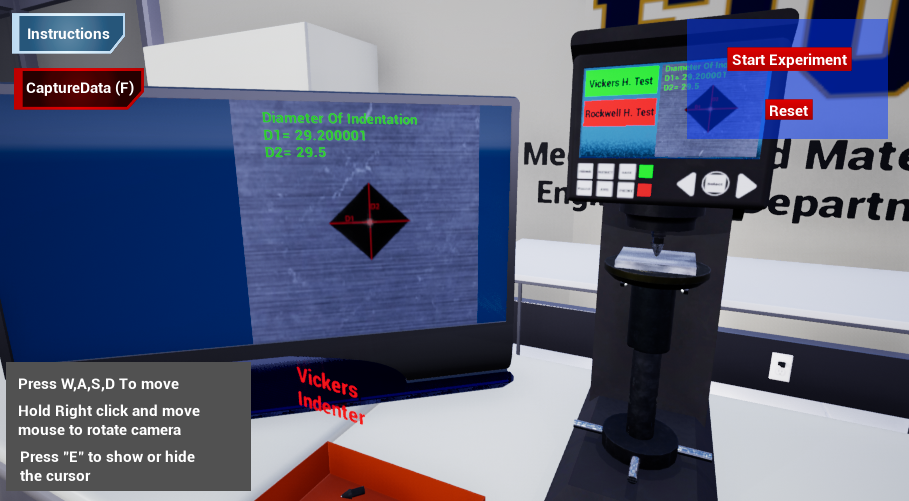

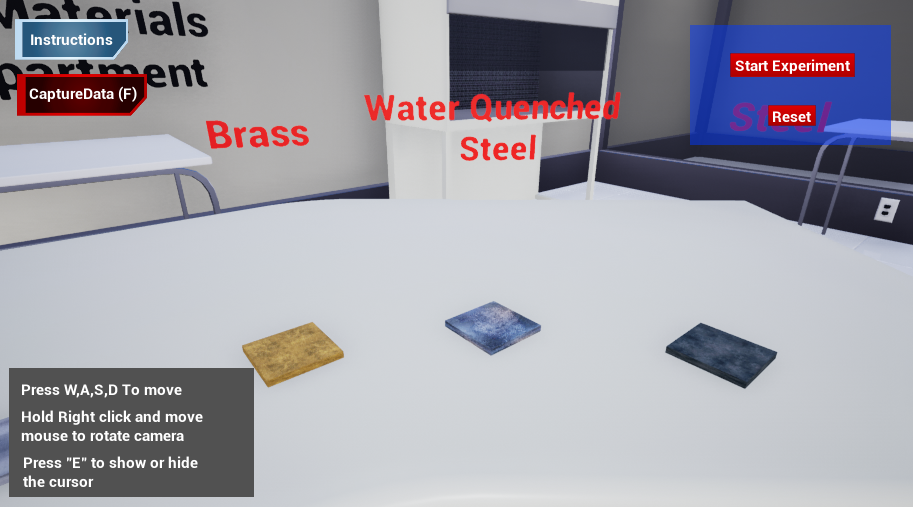

11. Tensile Test, Compression Test, and Hardness Tests (Vickers, Rockwell, Brinell): These virtual labs will cover essential material testing techniques, enabling students to analyze the mechanical properties of materials and their significance in engineering design.

12. Impact Testing:This virtual lab will teach students about the principles of impact testing, focusing on the significance of material toughness in engineering applications. Students will learn how to perform Charpy and Izod impact tests and analyze the results to assess the material's resistance to impact loading.

13. Strain Gauge Trainer: In this virtual lab, students will explore the use of strain gauges in measuring material deformation under various loading conditions. They will gain hands-on experience in selecting, installing, and calibrating strain gauges, as well as interpreting the data obtained from these devices.

Benefits of Virtual Labs in Mechanics of Solids and Fluid Mechanics Education

The implementation of PNX Labs' virtual labs at Florida International University will provide numerous advantages for both students and educators, including:

1. Enhanced Accessibility: Virtual labs enable students to access laboratory experiments from any location and at any time, provided they have a computer and an internet connection. This increased accessibility allows students to engage with course material more effectively, encouraging independent exploration and ownership of their learning.

2. Cost-Effectiveness: The development and maintenance of traditional labs can be expensive, often requiring significant investments in equipment, infrastructure, and personnel. Virtual labs, however, are a more cost-effective solution, eliminating the need for physical lab spaces and reducing maintenance costs.

3. Improved Safety: Virtual labs provide a safe environment for students to learn and experiment, removing the risks associated with handling hazardous materials, operating heavy machinery, or working with high-pressure systems.

4. Flexibility and Adaptability: Virtual labs offer a flexible and adaptable learning environment, enabling students to focus on specific topics or experiments that align with their interests or academic goals. Additionally, these labs can be easily adapted to accommodate diverse learning needs and preferences, ensuring a more inclusive educational experience.

5. Real-Time Feedback and Assessment: PNX Labs' virtual labs will provide students with real-time feedback on their performance, enabling them to identify and correct misunderstandings or errors immediately. This instant feedback can help students build a stronger foundation in mechanics of solids and fluid mechanics and support instructors in identifying areas where students may need additional support.

6. Environmental Sustainability:By reducing the consumption of materials, energy, and resources, virtual labs contribute to a more sustainable approach to engineering education, minimizing waste and promoting responsible use of resources.

Conclusion

Florida International University's decision to invest in PNX Labs' virtual labs for mechanics of solids and fluid mechanics reflects the institution's commitment to providing its students with a state-of-the-art learning experience. As engineering education evolves to meet the demands of the 21st century, virtual labs offer a powerful, innovative, and efficient solution for teaching complex concepts and skills. With the implementation set to begin in the Fall of 2023, FIU's partnership with PNX Labs promises to transform the learning experience for students and prepare them for successful careers in engineering and beyond.