Engineering Virtual Labs for Florida International University

Virtual Labs Instrumentation and Thermalfluid

Florida International University (FIU) has taken a big leap in innovative and immersive education by implementing a series of virtual labs for engineering students. The labs, developed by PNX Labs, enable students to conduct experiments, perform calculations, record data, and modify key variables using real instrument models in both windows and HTML platforms. The simulations are based on data gathered from actual experimentation performed by the faculty, ensuring that the virtual labs generate data that is consistent with the real world.

Given the current challenges of the COVID-19 pandemic and the economic crisis faced by several nations, virtual labs provide an effective means of delivering education in STEM programs, where laboratory experiences are essential. PNX Labs is fully committed to delivering the best-customized virtual labs in the market using its proprietary platform. Since April 2020, PNX Labs has developed over 1000 virtual experiments to support universities in continuing with their educational agenda.

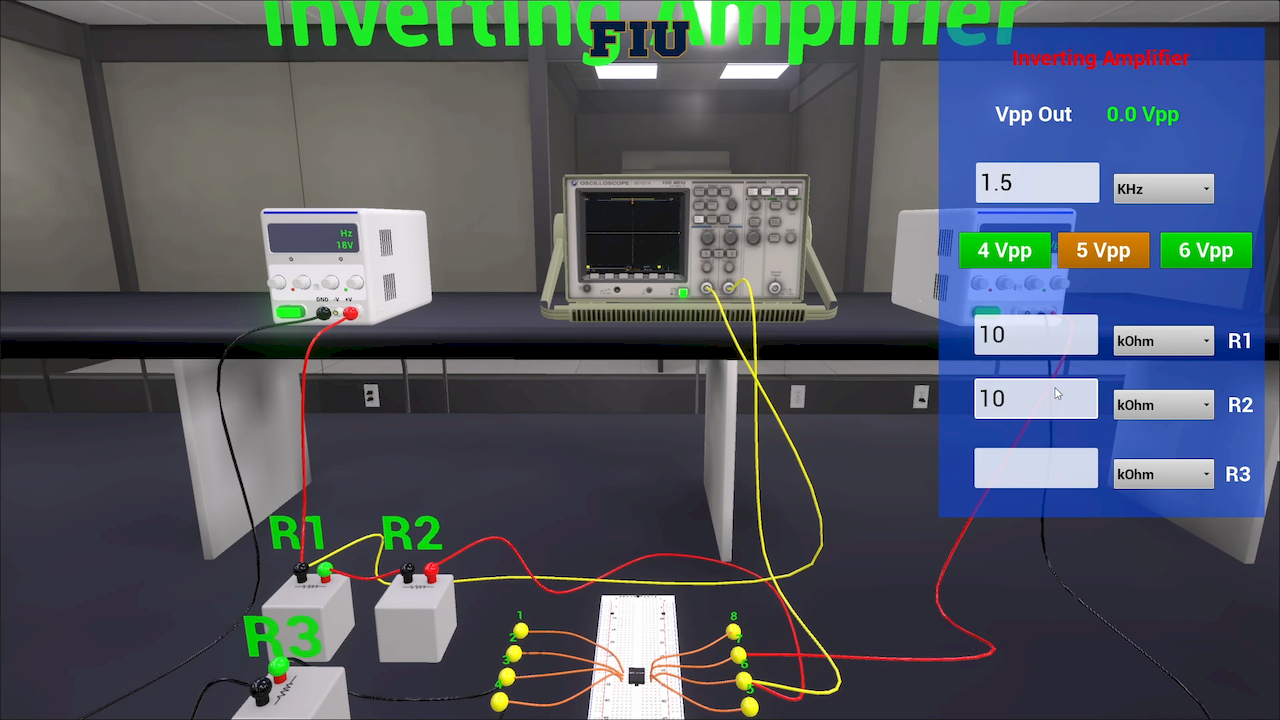

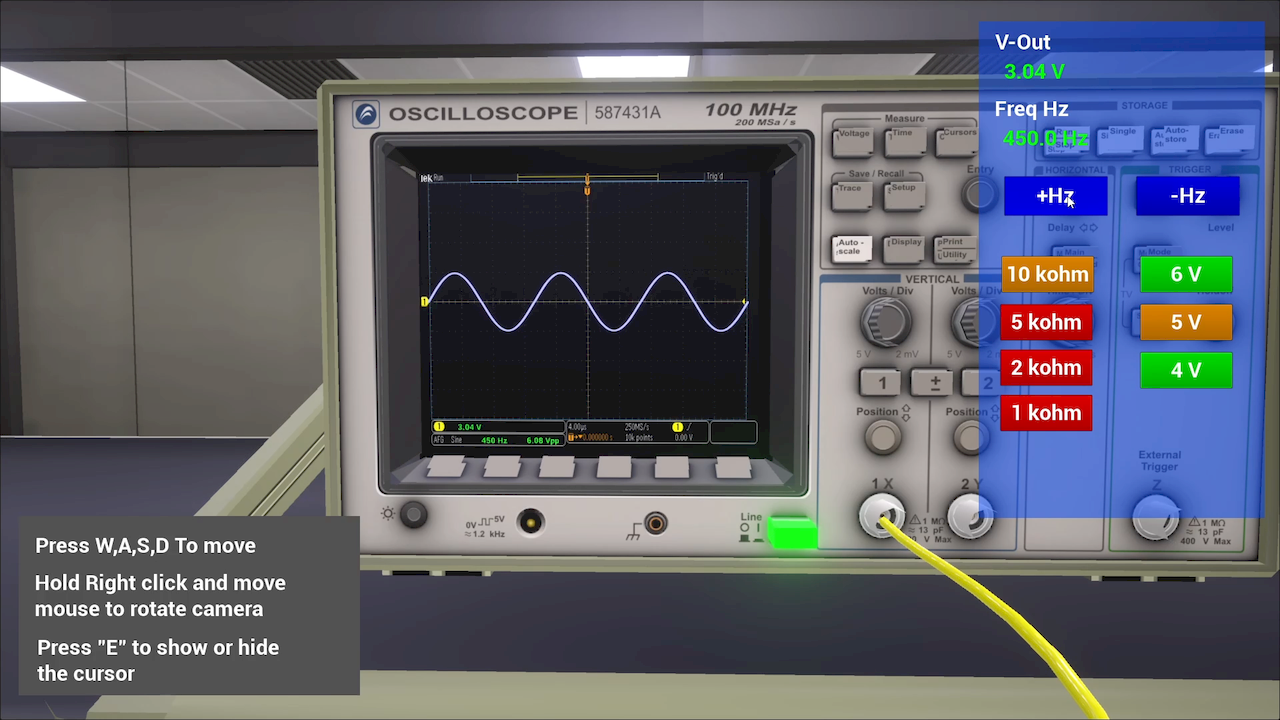

The virtual labs at FIU will include a range of experiments such as strain gauge as a force sensor, thermocouple as a temperature sensor, passive filters, operational amplifier, air speed measurement, heat transfer, and pipe friction. These experiments have been designed to enable students to learn from real experimentation from the comfort of their homes. By the end of 2021, the university plans to have a full set of virtual labs to provide students with an opportunity to experience hands-on laboratory work in engineering, without physically being present in the lab.

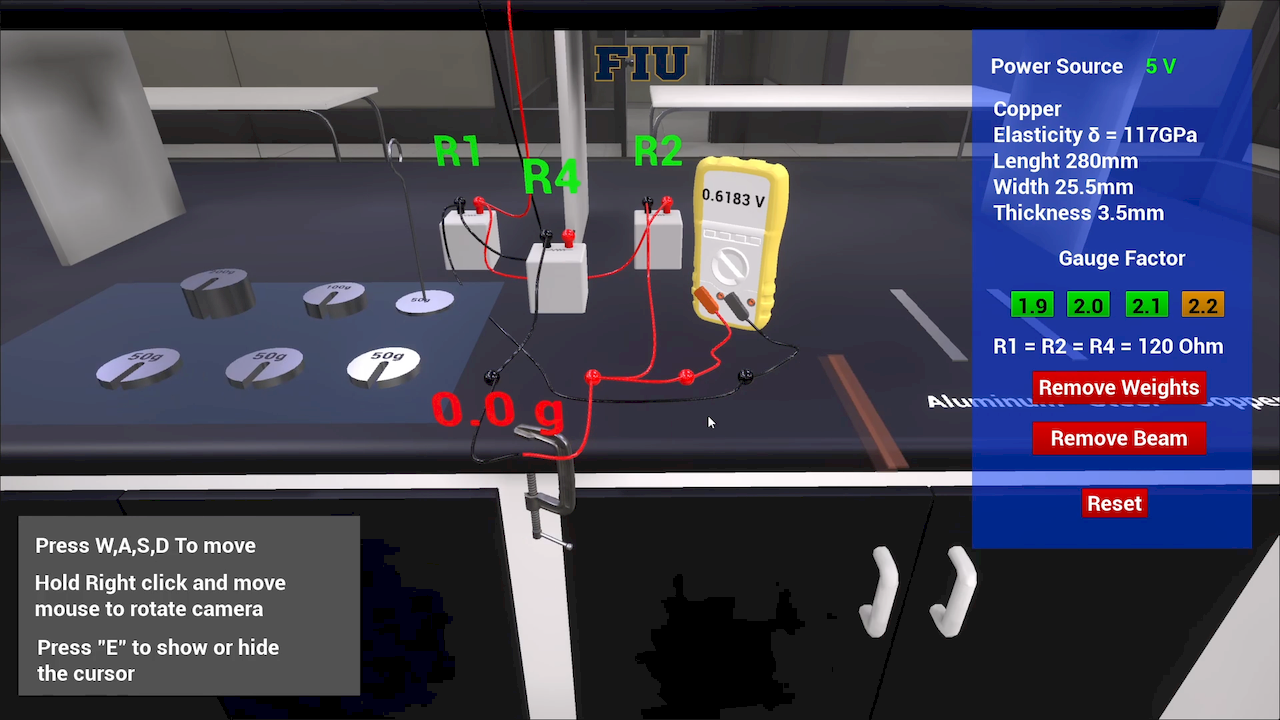

The strain gauge experiment involves using a strain gauge as a force sensor to measure force in different situations. This experiment will enable students to understand the concepts of strain and deformation, as well as the use of strain gauges to measure force.

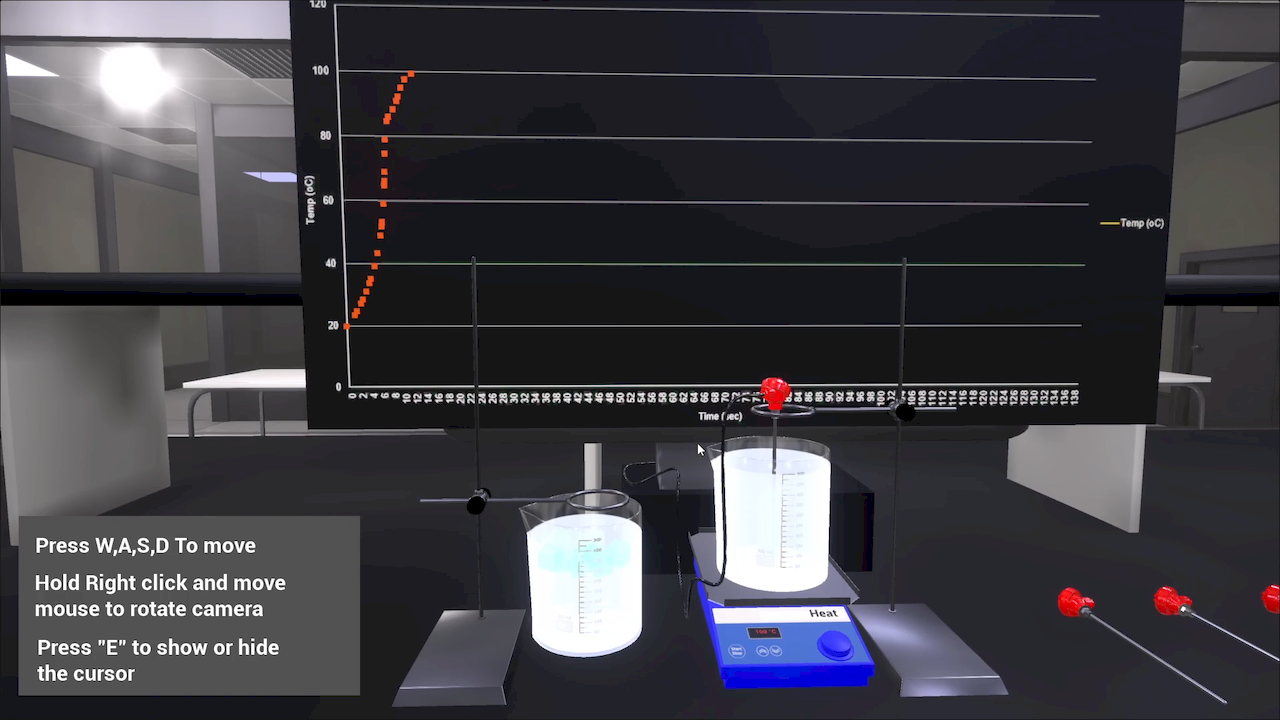

In the thermocouple experiment, students will learn how to use a thermocouple as a temperature sensor. This experiment will provide students with an understanding of temperature measurement, thermocouples, and temperature measurement instrumentation.

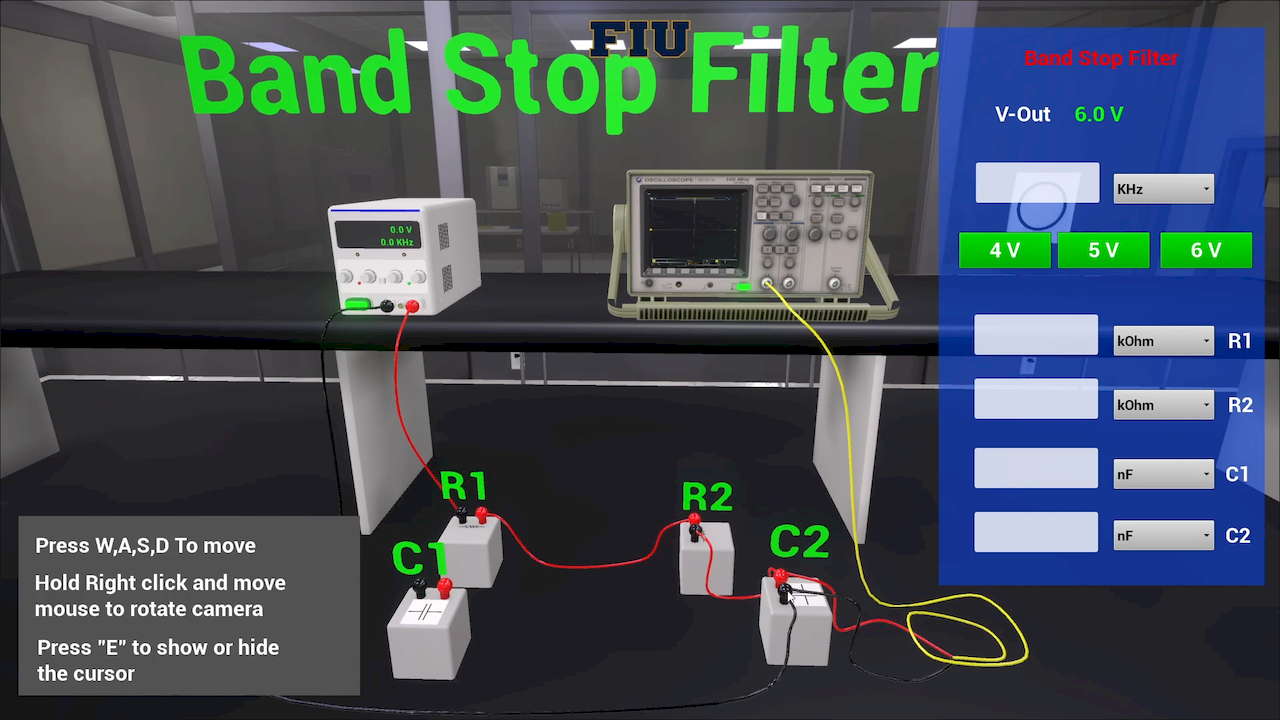

The passive filter experiment includes RC and RL filters, which are used in signal processing applications. In this experiment, students will learn how to design and implement these filters, as well as how to use them in practical applications.

In the band-pass filter experiment, students will learn how to design and implement band-pass filters, which are used in signal processing applications. This experiment will enable students to understand the concepts of band-pass filters and their practical applications.

The operational amplifier experiment includes learning how to use operational amplifiers as well as understanding their applications. Students will learn how to use op-amps in amplifiers, filters, and other signal processing applications.

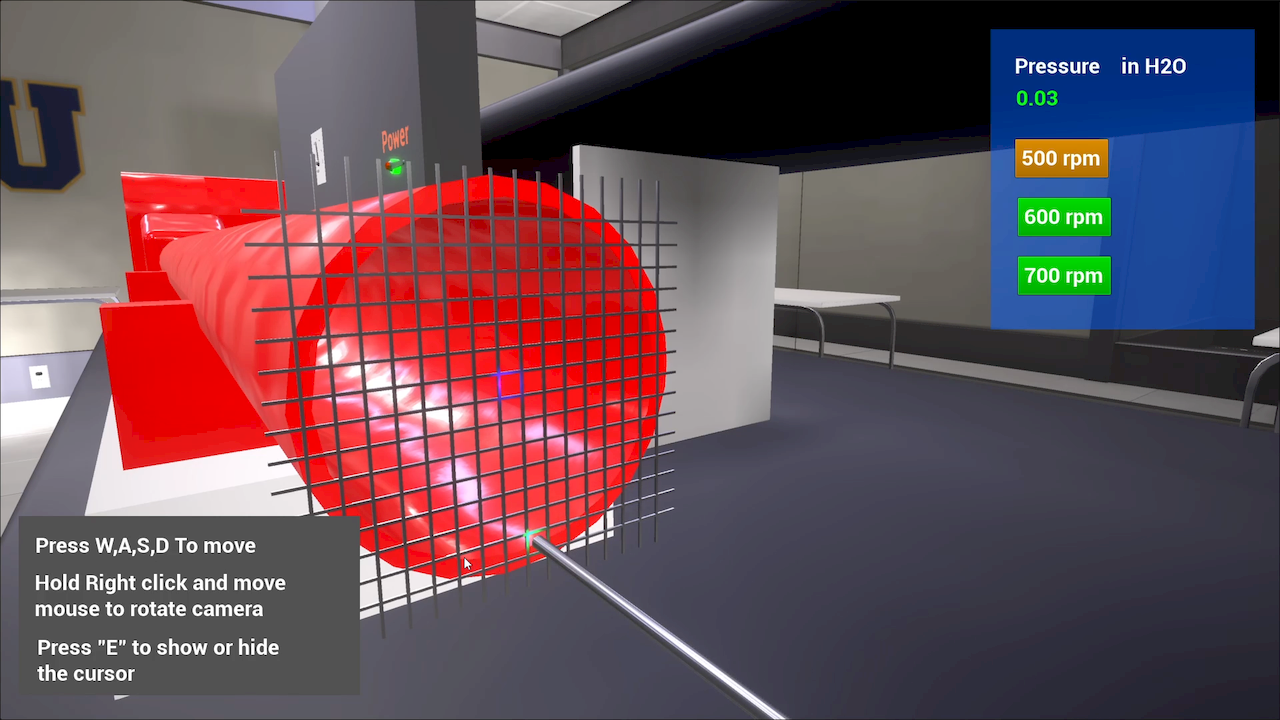

In the airspeed measurement experiment, students will learn how to measure airspeed in different conditions. This experiment will enable students to understand the concepts of airspeed and how to measure it using different instruments.

The heat transfer experiments include extended surface heat transfer, transient heat transfer, cross-flow heat exchangers, and combined convection and radiation on a cylinder. These experiments will provide students with an understanding of heat transfer concepts and their practical applications in different scenarios.

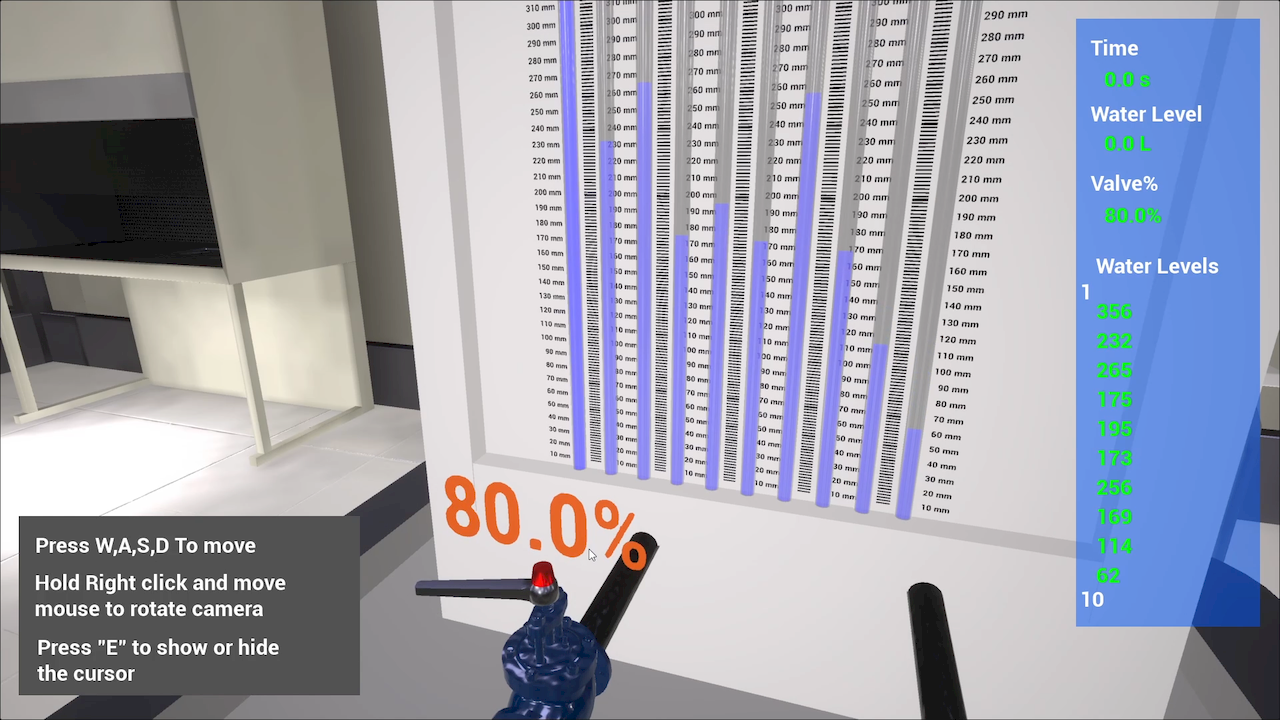

The pipe friction experiment involves the measurement of friction losses in pipes. This experiment will enable students to understand the concepts of pipe friction, fluid flow, and the measurement of pressure drop in pipes.

Virtual labs offer several advantages over traditional laboratory settings. They provide a risk-free environment for experimentation, can be customized to meet specific needs, are cost-effective, and can be accessed from anywhere. From a psychological perspective, virtual labs offer a more engaging and interactive learning experience that can promote collaboration and teamwork.

The implementation of virtual labs at FIU will provide students with an opportunity to experience hands-on laboratory work in engineering, without physically being present in the lab. This will allow students to learn at their own pace and convenience, with the added benefit of being able to repeat experiments as often as they like.