Machining Virtual Labs

Training workers with VR

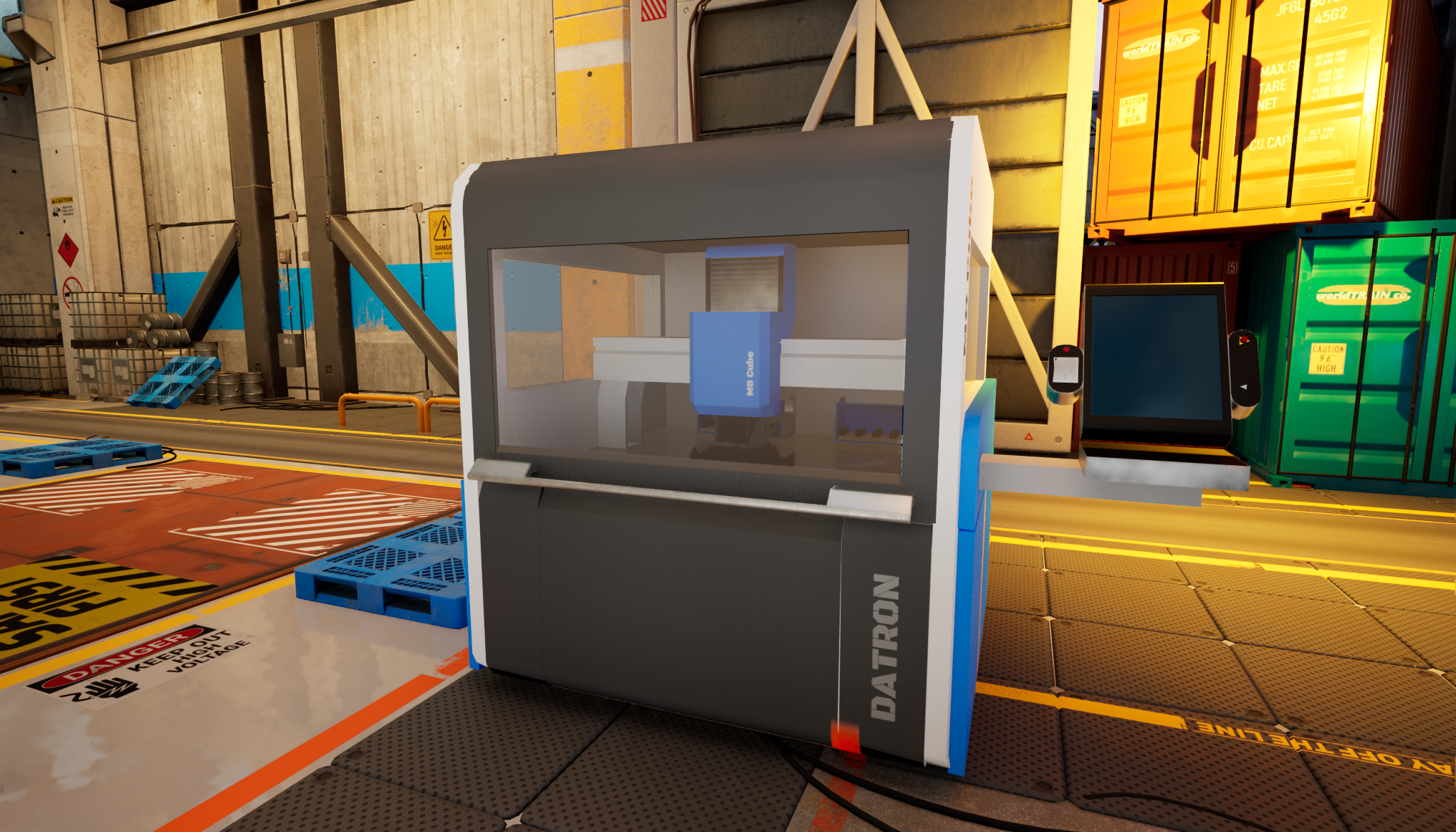

The manufacturing industry is continuously evolving, with new technologies emerging to make processes more efficient and cost-effective. One of the most significant advancements in recent years is the use of virtual reality (VR) to train workers to operate manufacturing machinery, such as CNC machines, laser cutters, and water cutters. In this article, we will explore the benefits of using VR to train workers to operate manufacturing machinery.

1. Enhanced Safety:One of the primary benefits of using VR to train workers is the enhanced safety it provides. Manufacturing machinery can be dangerous, and workers must be trained thoroughly to operate it safely. Traditional training methods, such as on-the-job training or classroom instruction, can put workers at risk of injury if mistakes are made. By using VR, workers can learn how to operate machinery in a safe and controlled environment, without the risk of injury to themselves or damage to equipment. This technology allows workers to practice different scenarios and learn from mistakes in a safe and controlled environment.

2. Reduced Downtime:Traditional training methods often require machines to be taken offline, resulting in costly downtime. By using VR to train workers, machines can continue to operate at full capacity while workers train in a virtual environment. This technology allows workers to gain hands-on experience without interrupting production, reducing downtime and increasing productivity.

3. Cost-Effective:Traditional training methods can be costly, requiring the use of specialized instructors and real machinery. In contrast, VR training is cost-effective, eliminating the need for real machinery and reducing the cost of specialized instructors. VR technology allows workers to practice on virtual equipment, providing them with the experience and knowledge needed to operate real machinery safely and efficiently.

4. Increased Engagement and Retention:Traditional training methods can be tedious, leading to low engagement and retention rates. However, VR training provides an interactive and engaging approach to learning, increasing engagement and retention rates. Workers can interact with virtual equipment, practice operating machinery, and receive instant feedback on their performance. This immediate feedback allows workers to quickly identify areas for improvement and make adjustments to their technique, increasing their confidence and skill level.

5. Flexibility:VR training provides flexibility for workers to train at their own pace and on their own schedule. Workers can practice operating machinery at any time and from any location, as long as they have access to the virtual environment. This flexibility makes it easier for workers to fit training into their busy schedules and ensures they receive the necessary training to operate machinery safely and efficiently.

6. Scalability:VR training allows for the scalability of training programs. Traditional training methods can be challenging to scale, as they require specialized instructors and real machinery. However, VR training can be easily scaled to accommodate large numbers of workers, making it a valuable tool for manufacturing training programs.

7. Realistic Simulation:VR technology allows for the creation of realistic simulations of manufacturing machinery. Workers can practice operating machinery in a virtual environment that accurately replicates real-life manufacturing situations. This technology allows workers to experience different manufacturing scenarios, such as operating machinery in different positions, working with different materials, and performing different tasks. This realistic simulation provides workers with the opportunity to gain experience and confidence in their skills before applying them in real-world manufacturing situations.

In conclusion, VR technology offers several benefits for training workers to operate manufacturing machinery. It provides a safe, cost-effective, and engaging approach to learning, allowing workers to gain hands-on experience without interrupting production. VR technology also offers flexibility and scalability, making it a valuable tool for manufacturing training programs. As the manufacturing industry continues to evolve, the use of VR technology for training workers will become increasingly important, providing the necessary skills and knowledge to operate machinery safely and efficiently.

By Sofia Indira Calderón Alvarez

Contact Us