PNX Labs Breaks New Ground with VR Welding Training Developed for Prolec General Electric

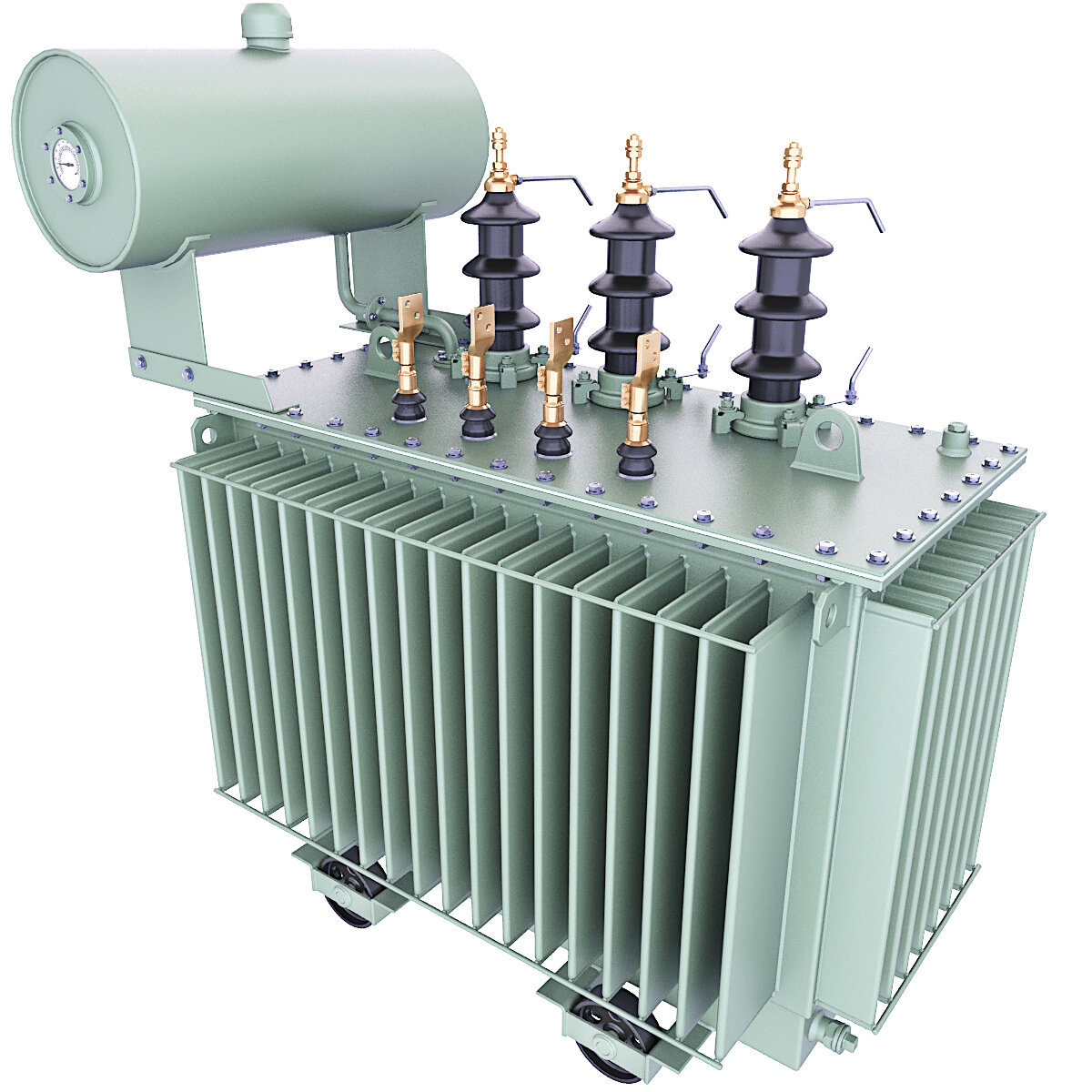

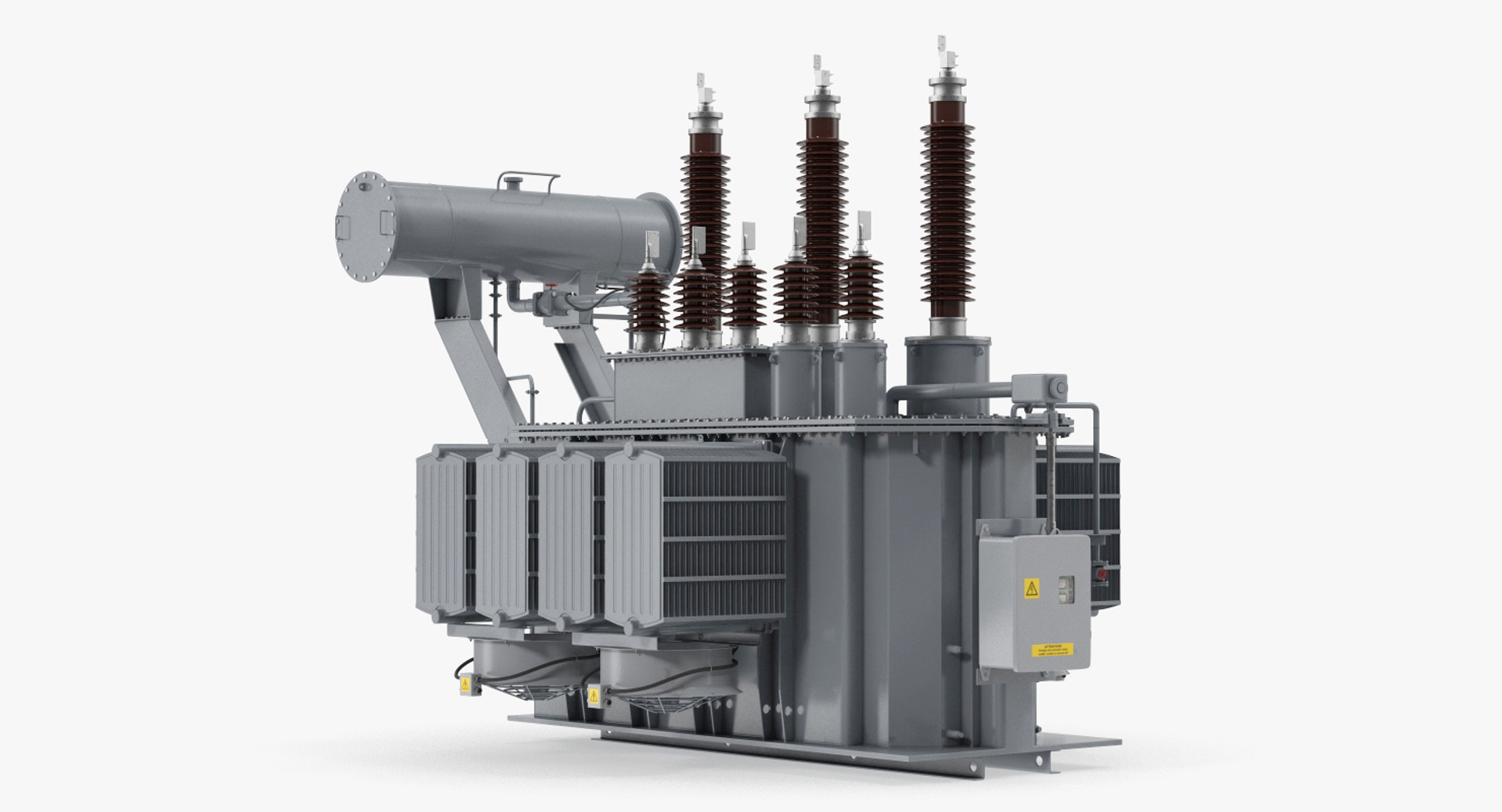

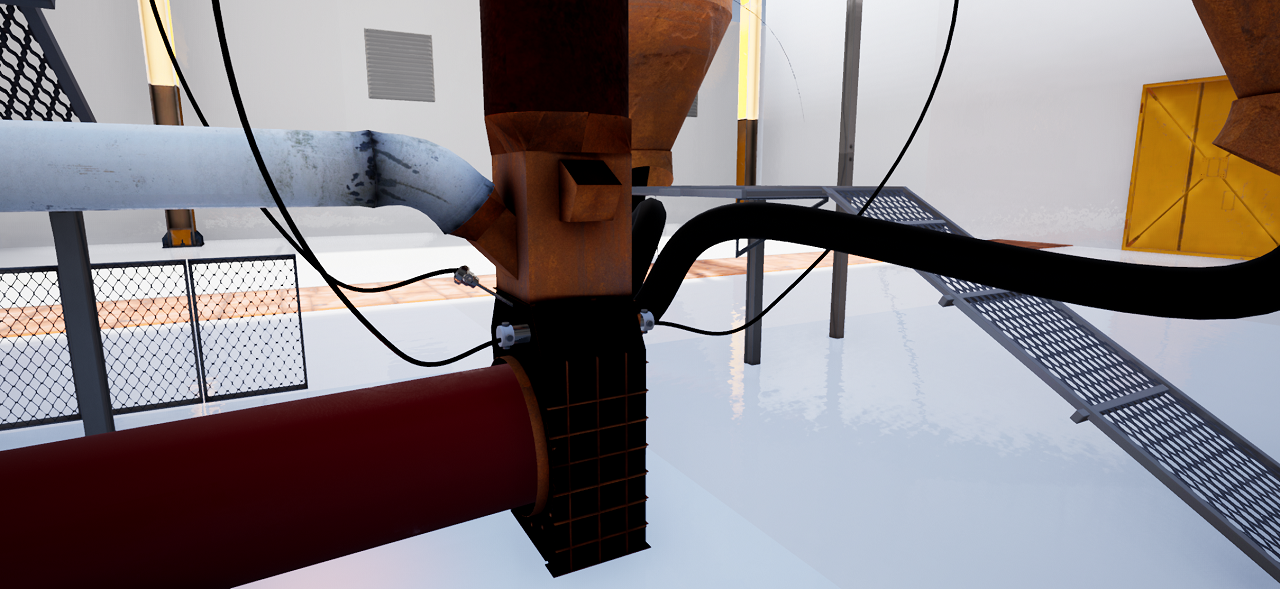

In the evolving landscape of industrial training, one revolution is steadily gaining momentum - the integration of virtual reality (VR) into training modules to enhance efficiency, safety, and cost-effectiveness. PNX Labs, a frontrunner in technological innovations, has recently embarked on a remarkable project for Prolec General Electric, where the spotlight is on transforming the traditional training paradigms for welders specializing in transformer manufacturing.

Reimagining Welding Training with Virtual Reality

Welding, a cornerstone in the fabrication and manufacturing industry, particularly in transformer production, is experiencing a renaissance in training approaches, thanks to the advent of VR technology. The project initiated by PNX Labs for Prolec General Electric targets this very aspect, giving a fresh perspective and a tech-savvy update to welding training.

Cutting-Edge Technology with Tangible Benefits

Under this initiative, welding training transcends conventional boundaries, embracing a virtual environment that is not just immersive and interactive, but also carries a host of benefits. Companies stand to cut training costs significantly, by up to 90%, an economic advantage that can potentially revolutionize budget allocations in organizations.

Furthermore, the training time is slashed by over 50%, translating to faster readiness of skilled welders for on-ground operations. But the benefits are not just confined to cost and time; let us delve deeper into the multi-faceted advantages this initiative brings to the table.

Safety First

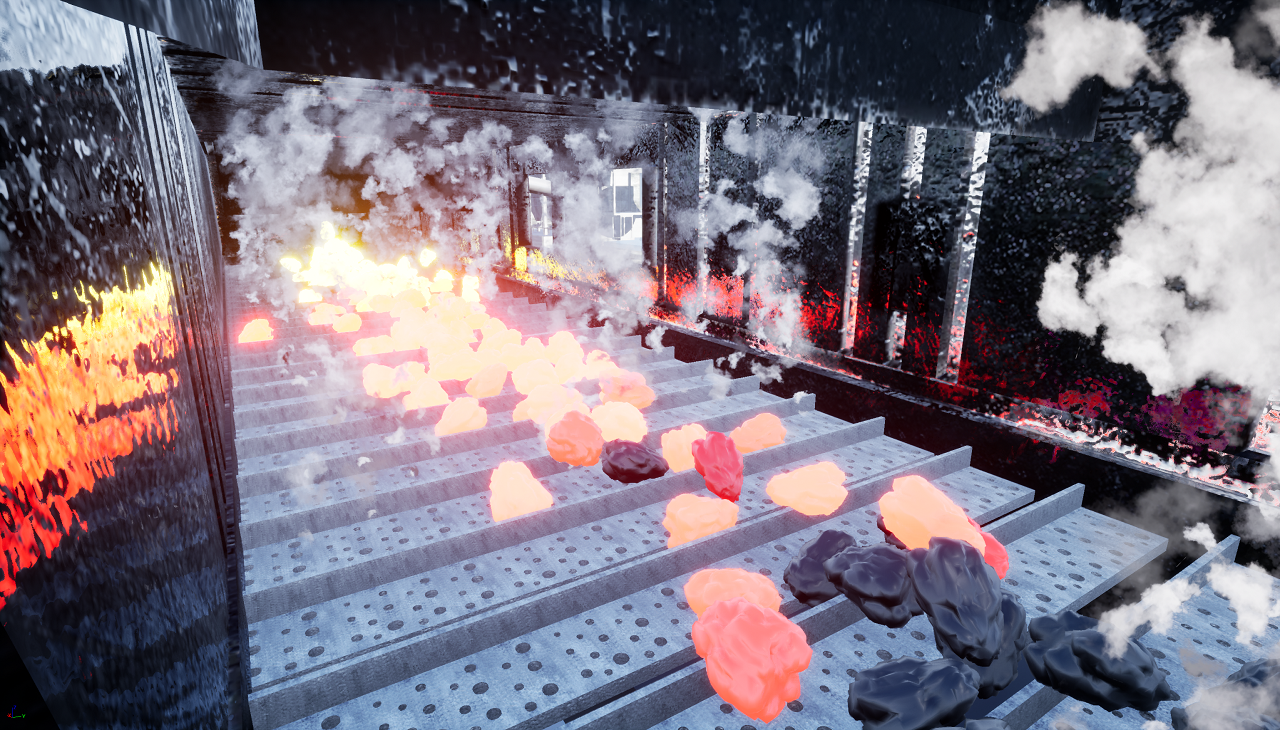

One of the standout benefits of virtual reality training is the safety it guarantees. Welders can now learn and hone their skills in a risk-free environment, eliminating the dangers associated with initial on-site training sessions. It fosters a learning atmosphere where mistakes are not just allowed but are integral to the learning process, devoid of any real-world repercussions.

A Hands-On Approach to Learning

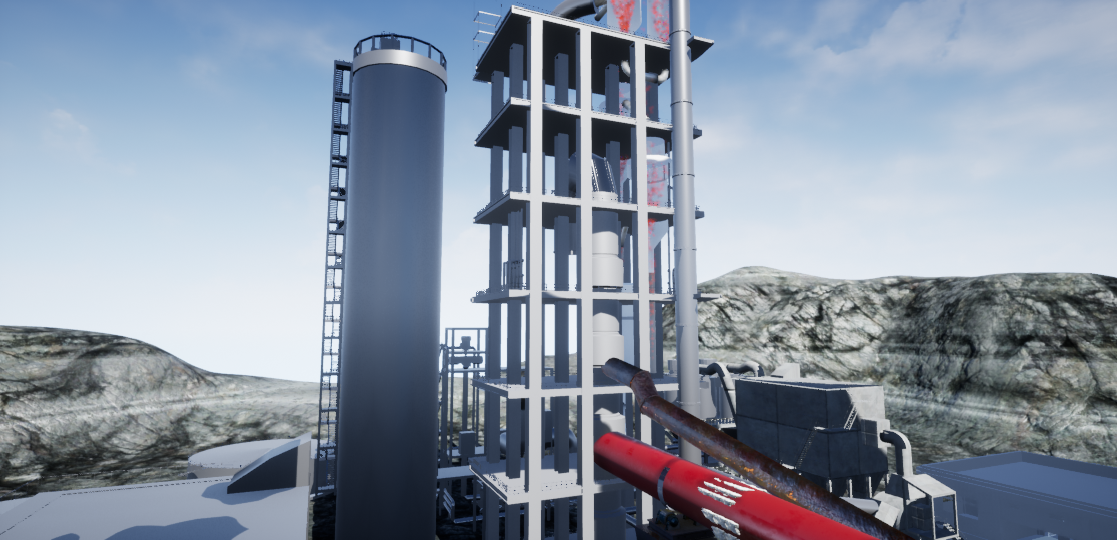

While traditional training often restricts learners to theoretical knowledge, VR training encourages a hands-on approach. Welders can immerse themselves in real-life scenarios, gaining practical knowledge and insights, which are pivotal in molding a skilled workforce ready to tackle on-ground challenges effectively.

Environmentally Friendly

VR training is not just economical; it’s eco-friendly too. By reducing the reliance on physical resources, it minimizes the carbon footprint, contributing positively to the environment. It is a step towards green and sustainable training solutions, aligning with the global emphasis on environmental consciousness.

Customizable Training Modules

The flexibility that VR offers is unparalleled. Training modules can be customized to suit individual learning paces, creating a learner-centric environment. It paves the way for a personalized learning experience, optimizing the training process for enhanced outcomes.

Expertise Meets Technology

By collaborating with Prolec General Electric, PNX Labs brings together a rich legacy of expertise and cutting-edge technology. This collaboration is a testament to a future where technology is leveraged to foster skill and excellence, setting a benchmark in the industry.

SEO Optimization: Targeting the Virtual Reality Training Niche

As the digital landscape continues to evolve, SEO optimization stands tall as a critical tool in reaching the right audience. By structuring content that resonates with searches related to “virtual reality training”, the initiative leverages SEO to reach stakeholders and potential learners, offering insights into this groundbreaking project.

A Beacon for Future Training Endeavors

As PNX Labs and Prolec General Electric forge a path adorned with technology and innovation, they also carve a niche that is likely to be emulated globally. The project stands as a beacon, showcasing the limitless possibilities that VR training holds, ushering a new era in industrial training modules.

Conclusion

In conclusion, the collaboration between PNX Labs and Prolec General Electric is more than a training program; it's a vision brought to life, where technology meets skill to forge a future that is safe, efficient, and forward-thinking. It's a blueprint for an era where training is not just about learning but experiencing, doing, and becoming proficient through a virtual yet realistic approach, transforming the very essence of training methodologies in the welding sector of transformer manufacturing.

As we stand on the cusp of this revolutionary endeavor, the industry eyes are set on this initiative, heralding a future that is not just technologically advanced but is grounded in safety, efficiency, and excellence. It is an invitation to experience a training methodology where virtual reality takes the center stage, redefining the contours of training in the welding industry, and setting a gold standard for others to follow.

By focusing on SEO optimization for virtual reality training searches, PNX Labs ensures that this innovative approach to welding training is accessible to industry stakeholders globally, marking a significant stride in leveraging digital strategies to enhance visibility and reach.

Embrace the future with PNX Labs and Prolec General Electric, where training meets innovation, offering a glimpse into the future of industrial training, characterized by efficacy, safety, and cutting-edge technology, all optimized for the digital age through strategic SEO implementation. Let us step into a future where virtual reality is not just a tool but a transformative force in welding training.