Elevating Cement Production Training through VR Technology: The Cemex Initiative

In an industry where precision is vital and mistakes come at a high price, advancing training methodologies is not just a luxury, but a necessity. Recognizing the potential to curb error rates and streamline the learning curve for production engineers, Cemex, a titan in the cement production and construction materials sector, has pioneered a transformative approach to training with its VR Training Program for Cement Production.

A Global Endeavor in Cement Production

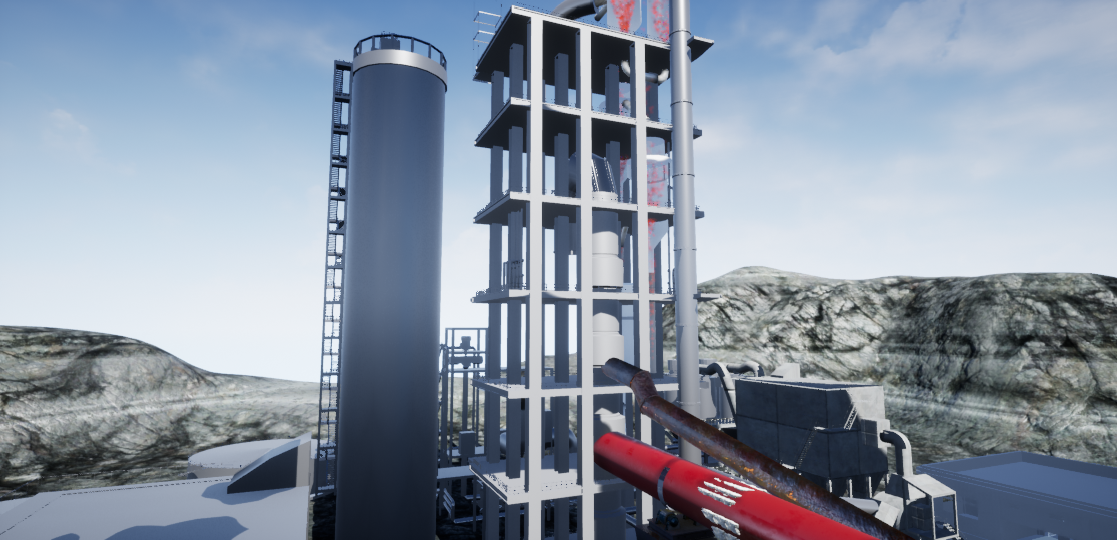

Cemex operates at a global scale, boasting a substantial share in the construction materials market, with a strategic spread of its production units across continents. From North America to Europe, North Africa, the Middle East, and Asia, Cemex's operations are at the heart of infrastructural development worldwide. This venture into virtual reality training showcases their commitment to innovation and efficiency, ensuring that their engineers across 50+ plants worldwide are equipped with the best training available.

Virtual Reality: The Future of Training

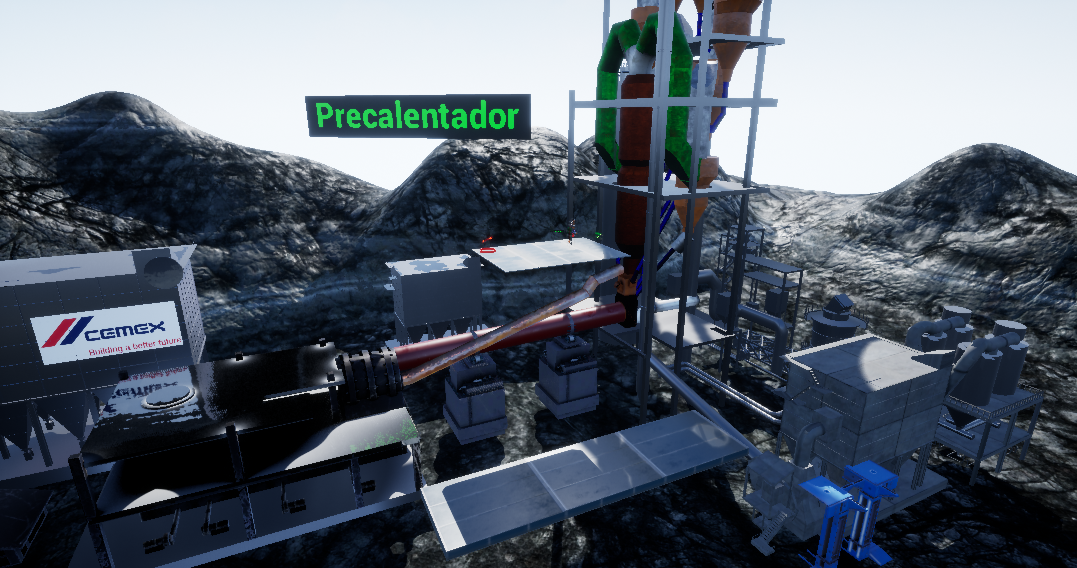

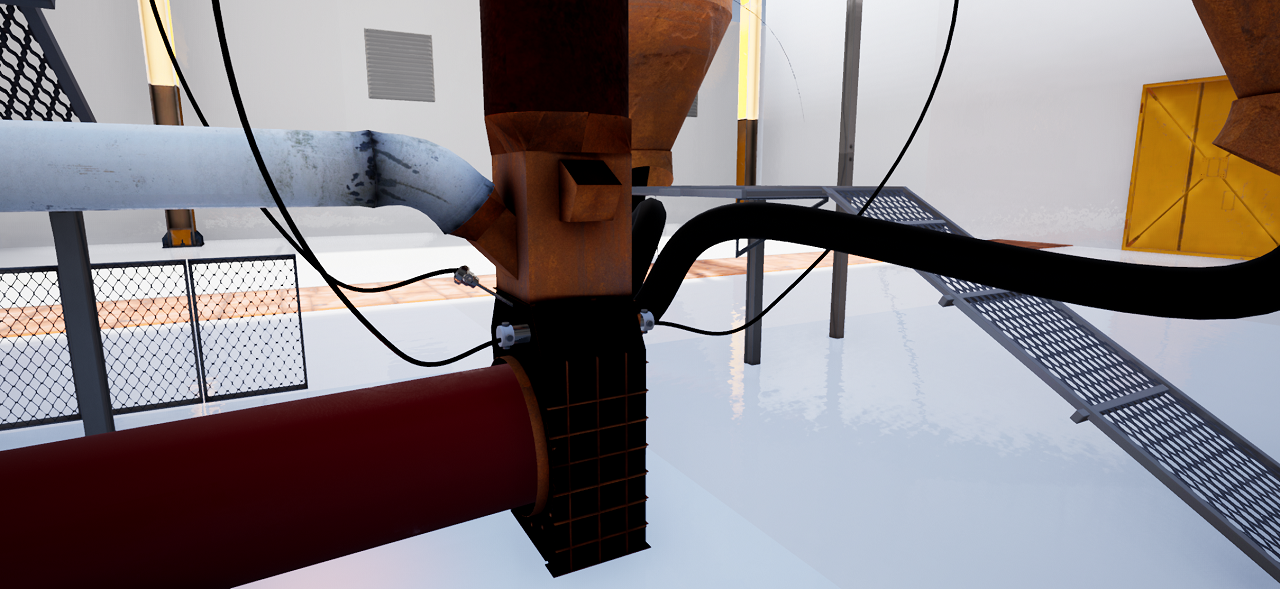

The VR training program was meticulously crafted by PNX Labs, with the ambitious goal of honing the skills of over 4,000 engineers responsible for cement production at Cemex. Embarking on this initiative in December 2022, it was conceived to be a comprehensive training approach, encompassing a broad spectrum of crucial areas in cement production, from mixture preparation to the final stages of packaging.

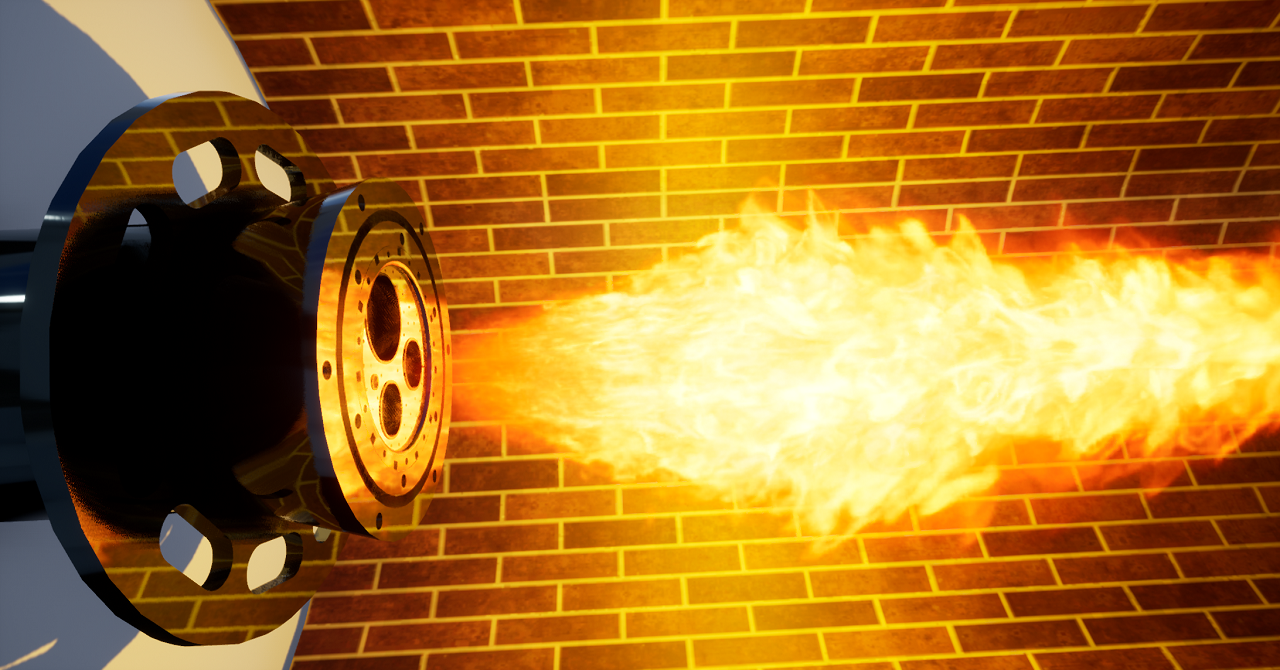

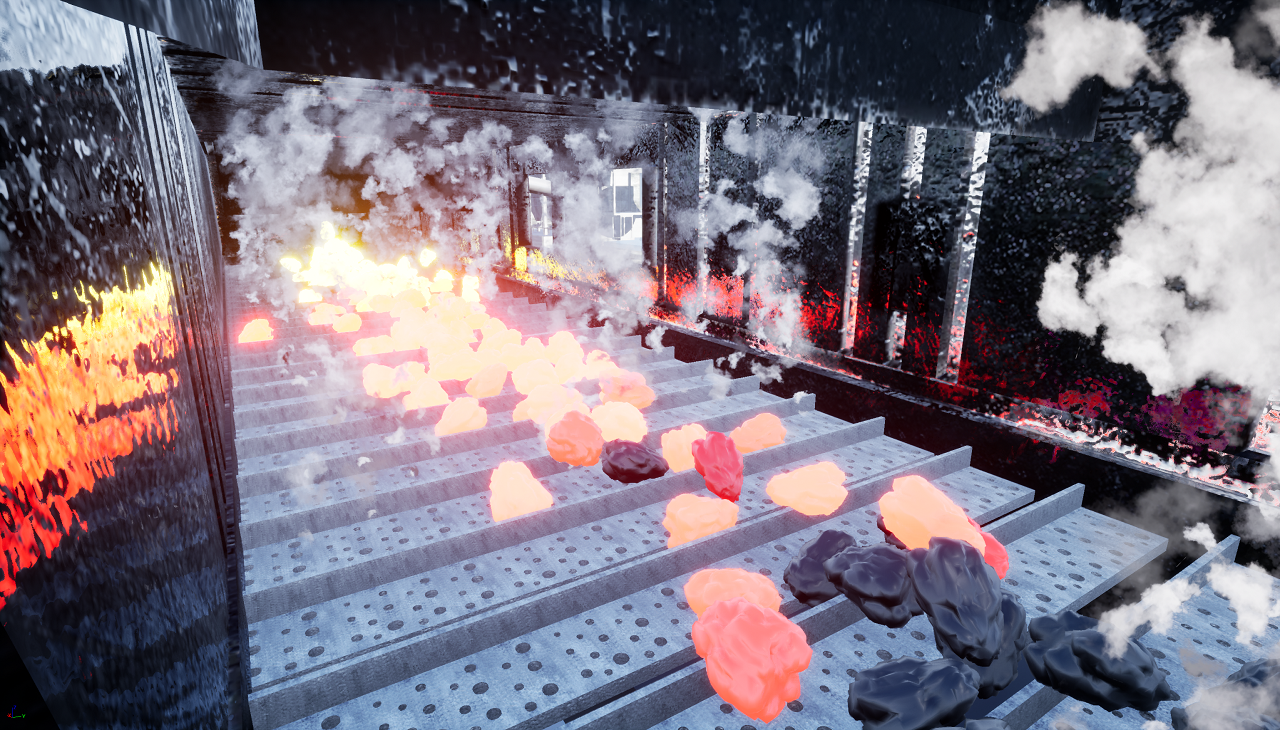

Each of the ten extensive modules that constitute the training program breaks down into 5 to 10 sub-modules, ensuring a thorough understanding of every critical variable involved in cement production. It promises a deep dive into areas like milling, preheater and calcination, rotary kiln operations, burner mechanisms, cooling processes, and concrete production, culminating with the packaging and hydration phases.

The Crucial Role of Preheater and Kiln Operations

A spotlight on preheater and kiln operations is warranted given their critical roles in the production process. A detailed understanding of the rotary kiln, responsible for the physical and chemical changes of materials to produce clinker, is imperative. The kiln's functioning, coupled with preheater actions that facilitate the raw mix's heating before entering the kiln, forms a pivotal part of the production process. The training encapsulates detailed insights into these operations, laying a strong foundation for engineers to comprehend and master the intricate details that influence the production quality.

An Investment in Knowledge and Efficiency

In an industry where errors can potentially cost millions of dollars per hour, training isn't just about education; it's a strategic investment. By nurturing well-trained engineers, Cemex not only mitigates risks but ensures a higher efficacy in operations, enhancing overall production quality. It moves towards creating a cadre of professionals well-versed in the nuances of cement production, ready to steer the company towards unprecedented heights of efficiency and precision.

Transformative Impact on New Hires

For newly hired engineers, the VR training program is a gateway to a world of knowledge, delivered in an immersive, realistic environment that facilitates faster learning and retention. It equips them with the skills and knowledge to navigate the complexities of the cement production process, setting a high standard for proficiency and expertise in the industry.

Advantages of Virtual Reality in Training

The usage of Virtual Reality in training brings forth a series of benefits:

- Safety: VR ensures a risk-free environment where engineers can learn without the hazards associated with on-site training.

- Cost-Effective: Reducing the need for physical resources, VR training is a cost-effective solution in the long run.

- Realistic Scenarios: Engineers are exposed to real-life scenarios, aiding in a better understanding and preparation for on-ground situations.

- Uniform Training: Ensuring a standard training regimen across global locations, VR brings uniformity and standardization in training.

Conclusion: Setting a New Benchmark in Industry Training

As Cemex stands on the verge of implementing this groundbreaking training program, it marks a moment of metamorphosis for the industry at large. It sets a new benchmark for training methodologies, leveraging cutting-edge technology to build a workforce grounded in knowledge, efficiency, and expertise.

The industry will keenly watch as over 4,000 engineers embark on this learning journey, underlining a critical shift towards embracing technology in training. The VR training program for cement production, with its comprehensive approach and detailed focus on preheater and kiln operations, promises to be a beacon of innovation, steering the future of training in the cement production industry.

By embracing the futuristic approach of VR-based training, Cemex is not just enhancing its operational efficiency but is taking a gigantic stride towards fostering a safer, knowledgeable, and proficient working environment. It’s an initiative where technology meets expertise, paving the way for a future of cement production characterized by precision, safety, and excellence.