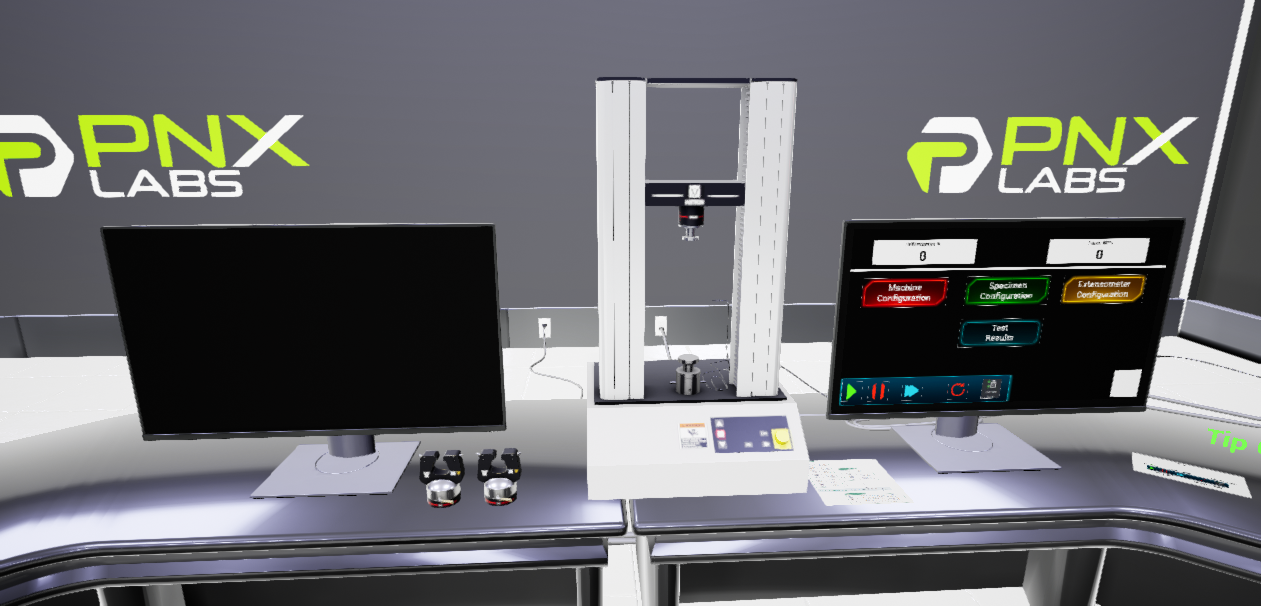

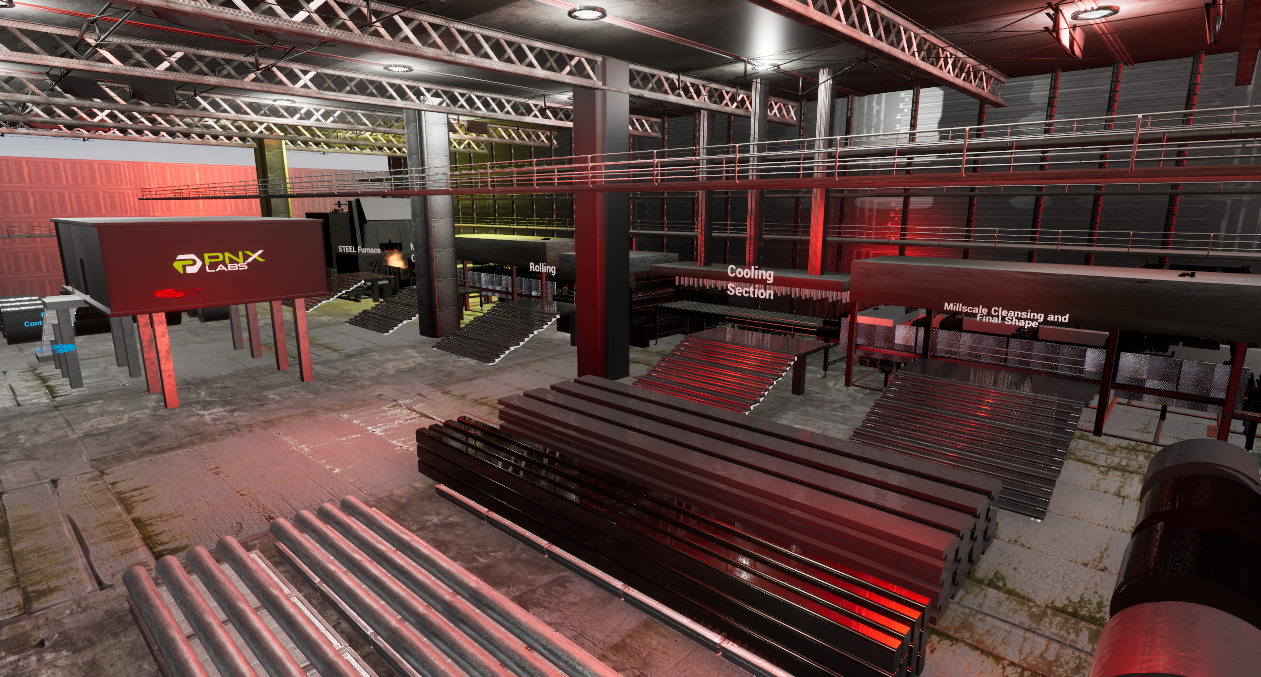

PNX Virtual Labs Fluid Mechanics

Virtual Reality Labs: Fluid Mechanics Unveiled

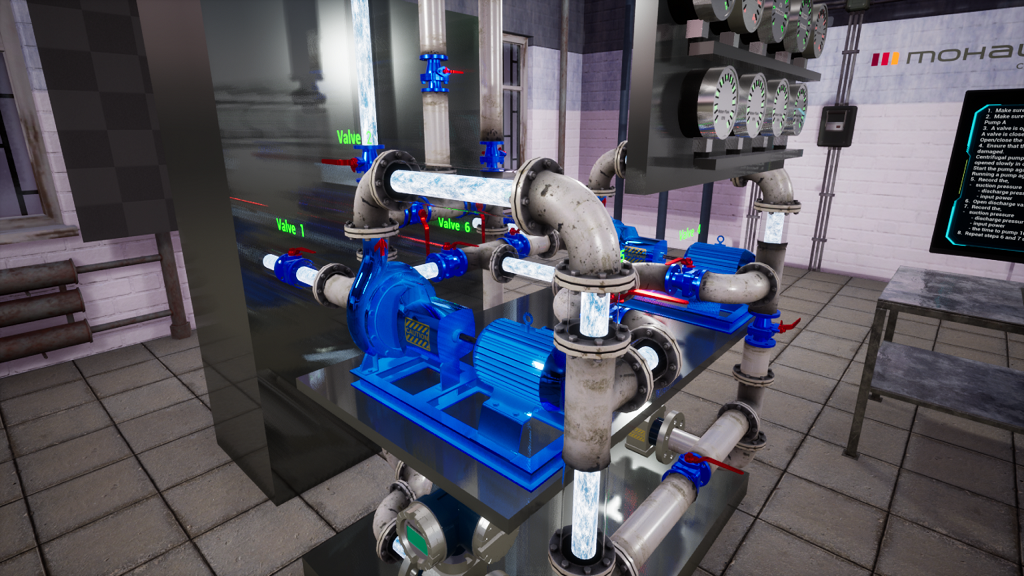

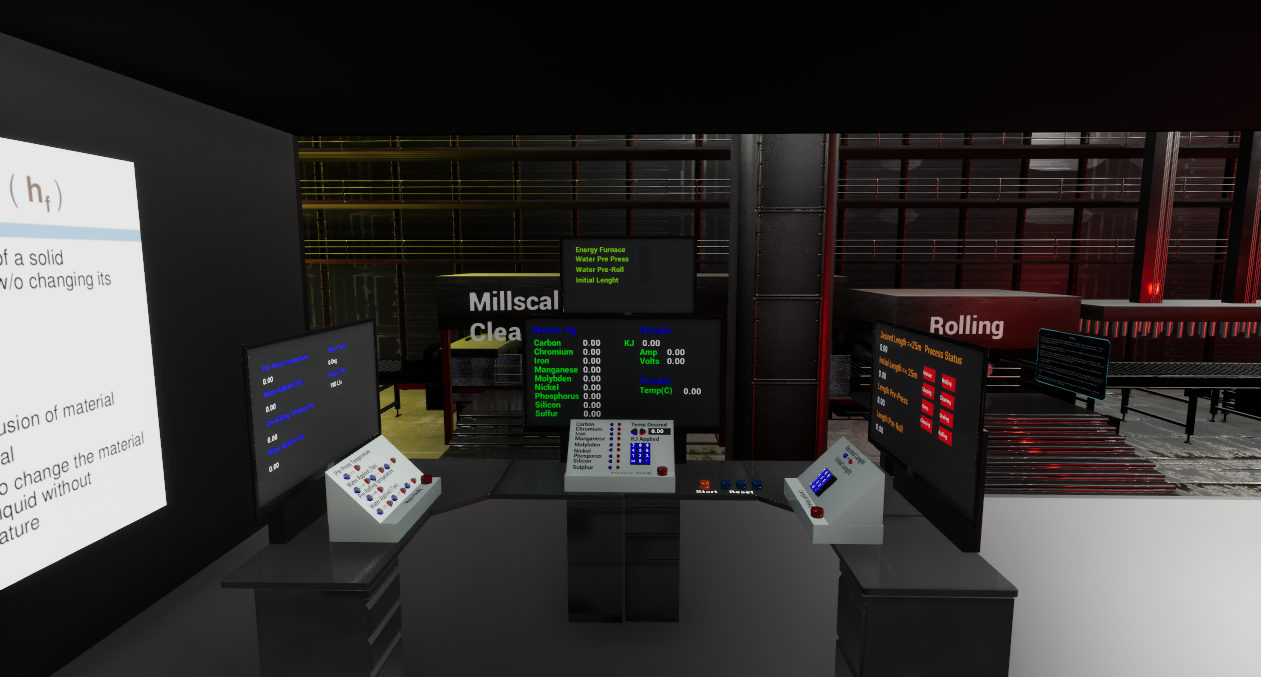

"Immerse yourself in the world of fluid mechanics with this comprehensive package of virtual labs tailored for Meta Quest. Dive deep into key experiments like Pressure Loss in Pipes, Orifice Calibration, and Centrifugal Pumps. Grasp the intricacies of Pumps in Series and Parallel, unravel the nuances of Pipe Friction, and get hands-on experience with Flow Measuring techniques. Designed with precision and interactivity in mind, these labs offer an unparalleled virtual reality experience, making complex fluid mechanics concepts more accessible and engaging than ever before."

Some of the Experiments in the full package are:

1. Virtual Lab Fluid Mechanics - Pressure Loss in Pipes

2. Virtual Lab Fluid Mechanics - Orifice Calibration

3. Virtual Lab Fluid Mechanics - Centrifugal Pumps

4. Virtual Lab Fluid Mechanics - Pumps in Series and Parallel

5. Virtual Lab Fluid Mechanics - Pipe Friction

6. Virtual Lab Fluid Mechanics - Flow Measuring

To access the simulation follow this link, install with Sidequest on your Meta Quest.